About the product

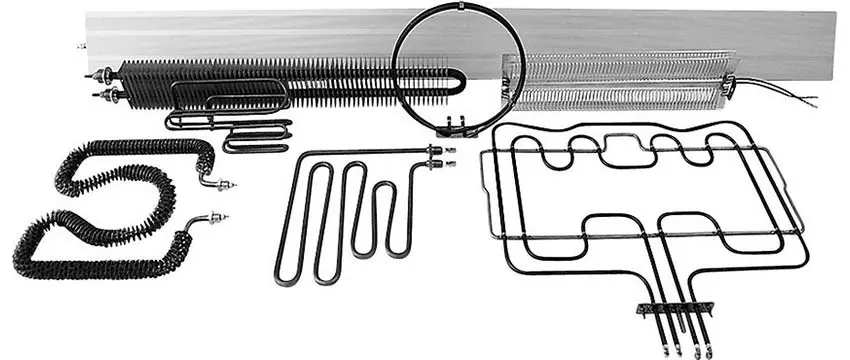

Tubular electric heaters are used wherever efficient heating of air (both moving and stationary) is required. Tubular heaters can be manufactured in both straight and bent forms, according to the customer's requirements.

- fans

- air curtains and air heaters

- ovens

- stoves

- grills

- bemars

- smokers

The tubular heating elements manufactured by us comply with the requirements of the PN-EN 603351 standard. We provide a CE declaration of conformity at the customer's request.

Radiator heaters

In some applications, where there is a need to improve heat extraction from the heater due to the high surface load, we can additionally use a radiator (steel or aluminium) mounted on the heater. Radiator heaters are most commonly used in air heaters where there is a large air blow.

Tubular heaters in the catering and gastronomy industry

Tubular heaters find many forms of use in industry, but also in machines used in small gastronomy. They are often found in restaurants and catering facilities in the form of kebab heaters, pizza heaters, fryer heaters and bemar heaters.

Manufacturing capabilities

Power

dependent on surface load*

Voltage

from 12V to 720V

Standard diameters

⌀7,9mm, ⌀8,35mm, ⌀10,6mm

Diameters for special order

⌀6,4mm, ⌀14mm**

Straight length

from 200mm to 7200mm***

Length of non-heating zone

min. 25mm

Radiator (option)

favir, sheet metal ribs, aluminium flat bar

Documents to download

Manufacturing limitations

* The maximum heater power we can offer depends mainly on the surface load present on the heater sheath, which is expressed in W/cm². The allowed surface load depends on the medium in which the heater will operate (e.g. water, oil, glycol, air) and the material from which the sheath is made. Our engineers will be able to adjust the best and safest power for the lifetime of the heater on the basis of the information received from you.

** The maximum length of the heating element in the straight state (before any bending) depends on its diameter and sheath material - we will not in every case be able to offer the maximum heater length given in the above table due to technological limitations.

*** Non-standard diameters are made to order which usually means a longer time to wait for a quote and a longer lead time. In the case of certain types of sheath material, there may be additional limitations.

In the case of bent heaters, the minimum internal bending radius is determined individually and depends on the sheath material and the degree of softening of the sheath in the production process. We would also like to remind you that, as a small-series manufacturer, so we are able to manufacture even individual heaters.

How to place an order for heaters and heating elements

We would like to point out that each heater project should be treated individually, so before you decide to place an order we recommend to consult with our sales engineers by sending a quotation request via e-mail. In order to provide you a price quote as quickly as possible, we will need a set of the following information:

- a photo or technical drawing of heating element

- heater type

- application of the heater (the device in which it will be used or the medium in which it will operate)

- expected operating temperature

- power [W] or resistance [Ω]

- voltage

- dimensions

- mounting method (head/threaded sleeve, flange, etc.)

- type of electrical connector or power cable

- for cables, please specify minimum length

- quatity

Please do not hesitate to contact us in advance if you have any doubts or questions.