About the product

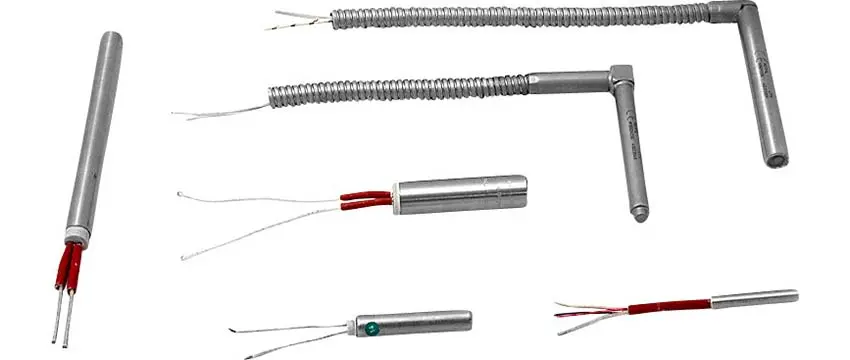

The design of the cartridge heater allows for heating elements with a higher power distribution per cm² of the heater shell than standard tubular heaters. Cartridge heaters are characterised by high heating performance at a relatively small size, with the application of cartridge heaters requiring good heat output collection. The production of this type of heater involves winding a resistance wire on a ceramic core and placing it in a chrome-nickel steel or brass shell. The resistance wire is additionally insulated with finely powdered magnesium oxide, compacted by vibration. These heaters are characterised by a rapid thermal response when power is applied, for which reason a heater operation control system is required in most applications. The outer diameter of the cartridge heater is made to the tolerance class specified by the customer. The exact dimension is obtained using wet grinding technology.

Cartridge heaters are used in heating plates, press tools, injection moulds or other metal parts that require rapid heating for the production process.

Finger heaters (cartridge heaters) in industry

Another common name for a cartridge heater is a finger heater. Cartridge heaters are widely used in many industries - they are placed in the holes of metal moulds and machine parts. In order to achieve good heat transfer from the heater to the heated metal part of the machine and to maintain the long life of the cartridge heater, it is necessary for it to fit tightly into the hole.

Cartridge heater for edgebanding machine

Finger or cartridge heaters are often used in the woodworking and furniture industry. The heater for the edgebanding machine is a cartridge heater - in the edgebanding machine, cartridge heaters are placed in the holes of the glue tank and in the glue roller of the edgebander and serve to melt the EVA or PUR glue that connects the chipboard to the edgeband.

How to place an order for heaters and heating elements

We would like to point out that each heater project should be treated individually, so before you decide to place an order we recommend to consult with our sales engineers by sending a quotation request via e-mail. In order to provide you a price quote as quickly as possible, we will need a set of the following information:

- a photo or technical drawing of heating element

- heater type

- application of the heater (the device in which it will be used or the medium in which it will operate)

- expected operating temperature

- power [W] or resistance [Ω]

- voltage

- dimensions

- mounting method (head/threaded sleeve, flange, etc.)

- type of electrical connector or power cable

- for cables, please specify minimum length

- quatity

Please do not hesitate to contact us in advance if you have any doubts or questions.